What are the drawbacks of 3D printing?

3D Printing is a technology with many merits. 3D printing has made prototyping and manufacturing of many components faster and more efficient. Despite the many benefits of 3D printing, the technology has several disadvantages. The drawbacks of 3D Printing technology are as follows:

1. Low energy efficiency: 3D Printing is an operation that requires a lot of energy. There are heaters. Lasers and motors must be operated with great precision to get accurate prints. A processing unit controls all these components, and often there is a great deal of heat generated, which needs to be controlled by a cooling unit or fans. When melting plastic with heat or lasers, 3D printers use 50 to 100 times more energy than injection molding, according to Loughborough University research. Direct laser metal deposition consumes 100 times more electrical power than conventional production, according to a study conducted in 2009 by The Environmentally Benign Manufacture, a research team devoted to examining the environmental effects associated with product manufacturing. 3D printers require a lot of energy for bulk manufacturing and are better suited for small-batch production runs.

2. High initial investment and expensive operation: The price of 3D printing machinery and materials makes the technology pricy. The cost of purchasing and installing an industrial-grade 3D printer requires hundreds of thousands of dollars, which makes the initial expenses of using the technology very high. Capital expenditures for a single machine begin in the tens of thousands of dollars and can reach hundreds of thousands or more. Additionally, compared to product materials used in conventional production, the materials utilized in commercial-grade 3D printers are more expensive. Unless the owner of a 3D printer is not commercializing their prints, it becomes a financial burden.

3. Toxic emissions: According to Illinois Institute of Technology experts, 3D printers used in confined spaces, such as homes, can produce potentially harmful fumes and carcinogenic particles. Their 2013 study found that while printing 3D objects, desktop computers could release significant amounts of ultrafine particles and potentially dangerous volatile organic chemicals. With PLA filament, the printers produced 20 billion ultrafine particles per minute, whereas ABS produced up to 200 billion particles per minute. Emitted radiations resemble the smoke from a cigarette and can enter the bloodstream or lungs, increasing the risk of cancer and other illnesses.

4. Limited materials: The materials that can be 3D printed are currently limited, with most materials being thermoset or thermoplastic polymers or photosensitive resins. Plastic is favored because it can be melted down into the desired shape fast and efficiently. Plastic’s strength capability can vary, so it might not be ideal for all components. Metal is a material that several businesses supply, although the final parts are frequently not completely dense. Although they haven’t yet been made commercially available, other specialist materials like glass and gold are being utilized. Metals can also be used for 3D printing, but this application of the technology is limited by the energy requirements and, consequently, the costs involved. More advanced uses of 3D printing, such as 3D printing of human organs, are still under development and will take several years to be commercialized.

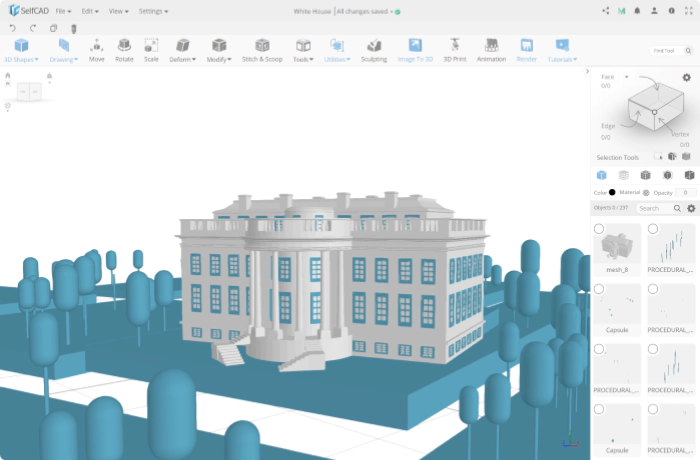

5. The equipment is not user-friendly: 3D printers are complicated machines, and users must be well-versed in several aspects to ensure their prints come out well. The temperatures required, the software expertise, knowledge about the material used for printing, and post-processing treatments are only some of the things that users must be aware of before operating a 3D printer. Once people start using a 3D printer, they will realize there is more to 3D printing than what they have read from articles online or what they learned from tutorials online. Expertise in 3D printing comes only with practice. 3D Designing is also an essential part of 3D printing. Learning 3D designing is also a complex process requiring time, consistent effort, and practice. However, learning 3D printing can be made easier using A 3D model maker tool like SelfCAD, which offers interactive tutorials to help users of any skill level pick up and learn 3D printing.

6. Dependent on toxic materials or materials that are not biodegradable: 3D printing is carried out either by adding multiple layers of photosensitive resins on top of each other or by extruding molten polymers into several layers to finally form a 3D structure. The downside is that most of these resins are toxic and have negative impacts, such as carcinogenic effects on humans. Polymers that are extruded in the case of 3D printing methods such as FDM are toxic in their molten form and even produce poisonous fumes. When hardened, they might not be biodegradable and will take several years to be broken down and pollute the planet. More research is required to make 3D printing with safer and biodegradable material possible and financially feasible.

7. 3D printing is a slow process: Although the possibilities for mass customization with 3D printers are endless, they are slow when it comes to bulk-producing many items. Printing may take several hours to days, depending on the size and quality of the printer. The slower the printers are, the more work is involved in product development. Depending on the materials used, it might take up to several weeks for businesses to create and produce 3D prints utilizing a variety of items.

8. Size of the final product: The size of the printer itself determines what kinds of parts it can print. Commercially available and reasonably priced 3D printers often have chamber sizes that are small enough to be transported and easily fit on a desktop. Usually, the larger versions are quite expensive because they can print larger forms and pieces. On the basis of existing technology, printing massive parts can also be time-consuming.

9. Accuracy of the prints: Currently, the majority of things produced using 3D printing technology are prototypes and test parts. The dimensions must be accurate to a degree not yet possible with the most cutting-edge technologies for engineers to validate whether or not the prototype or test part is practical. Despite recent developments, most 3D printing materials still require a disclaimer for accuracy levels; there is frequently a margin of error of about .1 of a millimeter, which in many engineering sectors is a fatal error.

10. Disruptive technology that can take away jobs: By altering product development, 3D printing has upended markets. 3D printing, often referred to as additive manufacturing, is the process of layer-by-layer connecting materials to create objects from a 3D digital model. Unlike subtractive manufacturing (conventional), which entails removing undesirable components from sizable chunks of solid material, it is different. The creation of intricate structural details is made easier by the 3D printing technique, which removes numerous steps utilized in traditional manufacturing. The fields of fast prototyping and tool development have seen a great deal of success as a result of these capabilities. It, therefore, doesn’t require a lot of labor expenses. As a result, using 3D printing may result in fewer manufacturing jobs. The reduction in manufacturing jobs could significantly impact the economy of nations that rely heavily on low-skill jobs. Robotics will probably have a far greater influence on this.

11. Copyright infringements and counterfeiting: One of the biggest drawbacks of 3D printing is counterfeiting. Anyone who has a product blueprint can swiftly forge products. Patent infringements will frequently increase, making it nearly hard to spot counterfeit goods. Patent and copyright holders will find it more difficult to enforce their rights as 3D printing technology develops and businesses that make one-of-a-kind products will be negatively impacted. Other illegal activities, such as counterfeiting currency by 3D printing the currency molds, are easily possible. With image-based measurement tools, keys can be 3D printed, leading to theft.

12. Production of dangerous weapons: Knives, weapons, explosives, and other deadly objects may all be easily made in three dimensions using 3D printers. Thus, making such weapons allows criminals and terrorists to operate undetected. Some criminal organizations have already produced card readers for bank machines using 3D printing technology. As 3D technology advances, it will likely become more affordable and user-friendly, which could increase the design and manufacturing of unauthorized weapons.

Conclusion

In conclusion, 3D printing has several disadvantages despite the multiple advantages of this technology. The major downsides of 3D printing lie in the areas of cost, energy requirement, scale, speed, and accuracy of the operations. More handicaps of 3D printing can be found in areas such as counterfeiting, illegal activities, and the production of dangerous weapons, as there is no regulation or control for purchasing 3D printers. 3D printing is also a disruptive technology that makes several human jobs obsolete and takes up several positions in manufacturing and even entertainment. Despite these obstacles, 3D printing has several positive uses, and 3D designing is an important skill to have to make the best use of 3D printing. Learn 3D designing fast with the SelfCAD interactive tutorials.