How Omniverse technology can benefit manufacturing businesses

Nvidia Omniverse is a multi-disciplinary simulation and collaboration platform developed by Nvidia that enables users to create, edit, and share 3D content in real-time across a wide range of industries and applications, including design, architecture, engineering, film, and gaming. Omniverse helps to combine various modeling tools and programs into a unified ecosystem.

It can benefit your business by providing the following advantages:

- Improved Collaboration: It enables team members to work together in real-time on 3D content, regardless of location or the tools used.

- Increased Productivity: With a unified platform, users can access various simulation tools and applications, reducing the need to switch between different software and saving time.

- Enhanced Visualization: The platform provides high-quality, interactive visualization capabilities, allowing teams to see their designs and projects in a more realistic manner.

- Better Design Process: Omniverse enables more accurate simulations and more efficient design iterations, leading to better products and faster time-to-market.

- Reduced Costs: By streamlining the design process, Omniverse can help reduce the cost of product development and improve profitability.

One of the most interesting opportunities provided by Omniverse for logistics or manufacturing companies is the Digital Twins technology.

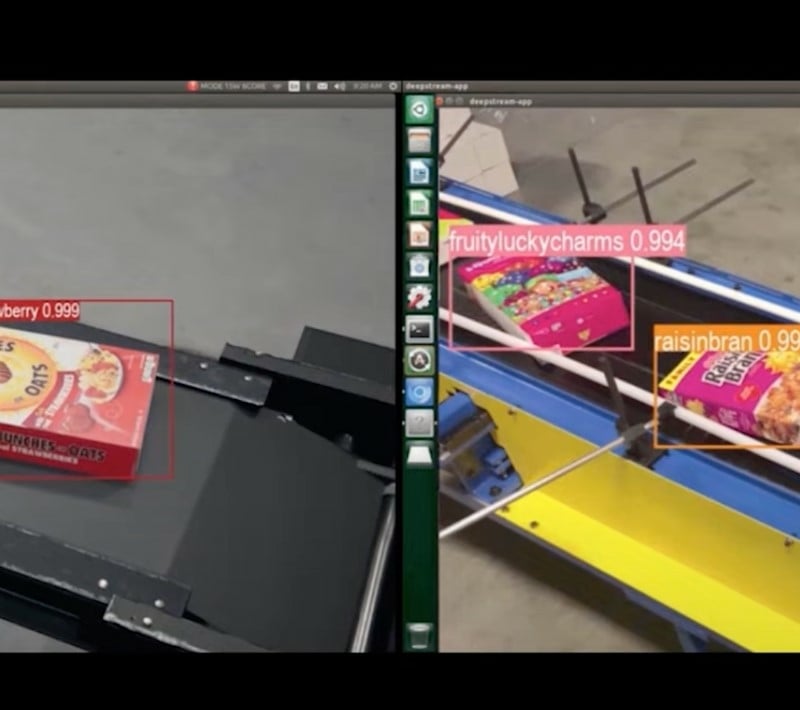

A digital twin is a virtual representation of a physical object, system or process created using data collected from sensors and other sources. The digital twin technology allows for real-time monitoring and analysis of physical objects, systems and processes, simulating their behavior and allowing for predictive maintenance and optimization.

The use of digital twins can lead to numerous benefits, such as:

- Improved operational efficiency: By continuously monitoring the performance of physical assets, digital twins can help identify inefficiencies and optimize operations.

- Predictive maintenance: By analyzing data from the digital twin, businesses can identify potential problems before they occur, reducing downtime and maintenance costs.

- Improved decision-making: Digital twins provide a wealth of data often used for decision-making, increasing the accuracy of forecasts and reducing risks.

- Improved customer experience: Digital twins can simulate and optimize customer experiences, such as product usage and service delivery.

- Better product design: By continuously testing and improving the digital twin, businesses can optimize product design, reducing costs and improving performance.

In today’s dynamic world, even companies that are very indirectly involved in digital innovation must keep an eye on the opportunities that computer technology provides them. After all, just the assembly line changed the production efficiency and brought to the fore those companies that could quickly adapt it to their operations. In the same way, the technologies embedded in Omniverse, in particular Digital Twins, enable many organizations to gain a competitive advantage. By optimizing their cycles and maximizing process efficiency without the need for physical experiments